| The TRANSCALOR -

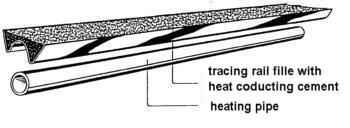

Tracing Rail When

used the TRANSCALOR - heat conducting

cement, the TRANSCALOR - tracing rail

offers a suitable product combination in

order to design the operation of trace

heating pipes with efficient results.

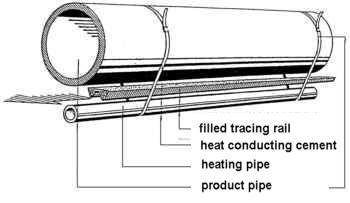

In addition to a reduction

of the assembly expenditure, a

considerable improvement of the

transmission from the trace heating pipe

onto the product pipe is achieved.

The tracing rail is a

specially shaped plate bed in which the

trace heating pipe lies on the one side

(support bed) and which, on the other

side provides space for receiving the

heat conducting cement.

Due to the correspondingly

shaped bed, the contact surface area with

the trace heating pipe is designed as

large as possible.

The contact surface area

toward the product pipe is created by the

deformation of the heat conducting cement

when the filled tracing rails are pressed

against it.

The TRANSCALOR - tracing

rails must be filled with the TRANSCALOR

- heat conducting cement before

installation and then must be pressed

simultaneously with the heating pipe

against the product pipe.

By tightening down the

tensioning bands, the TRANSCALOR -

tracing rail is pressed against the

product pipeline so that the heat

conducting cement placed into the tracing

rail fills up the existing space between

the two pipelines and can therefore

achieve optimum heat transfer.

| Content | TRANSCALOR -

Tracing Rail | Home |

|